You’re hosting a dinner party. Everything’s going perfectly until your guests start texting you the next day with stomach issues. Sounds like a nightmare?

Here’s the scary truth: You’re more likely to get food poisoning at home than at most restaurants.

I know what you’re thinking. “But restaurants are gross! I’ve seen Kitchen Nightmares!” Yet the data tells a different story. While 48 million Americans get food poisoning every year (that’s 1 in 6 people), professional kitchens have cracked the code on keeping people safe.

Want to know their secret? It’s not just about washing your hands more often.

Top chefs follow a simple rule that most home cooks have never heard of. And once you understand it, you’ll never look at your kitchen the same way again.

The $1.9 Million Mistake That Changed Everything

Let me tell you about the day that revolutionized restaurant food safety forever.

It was 1993. Jack in the Box was serving what seemed like perfectly good hamburgers. Kids were happy. Parents were satisfied. Then everything went wrong.

Four children died. 178 others suffered permanent damage. All because burgers were cooked to 140°F instead of 155°F. Just 15 degrees made the difference between a happy meal and a national tragedy.

The company paid out millions in lawsuits. But more importantly, this disaster taught the entire food industry a crucial lesson:

Small mistakes have massive consequences.

Today, a single food safety violation can cost restaurants up to $1.9 million. Some never recover. Chi Chi’s, once a 200-location chain, closed permanently after their 2003 outbreak. Gone. Forever.

That’s why professional chefs don’t leave anything to chance.

The Color-Coded System That Saves Lives

Walk into any serious restaurant kitchen and you’ll notice something weird: cutting boards in seven different colors.

This isn’t some interior design choice. It’s a life-saving system that creates invisible barriers between dangerous foods.

Here’s how it works:

- Red = Raw beef and pork

- Yellow = Raw poultry

- Blue = Raw fish and seafood

- Green = Fresh fruits and vegetables

- White = Dairy and baked goods

- Brown = Cooked meats

- Purple = Allergen-free prep

But here’s the part that’ll blow your mind: The cutting boards are just the beginning.

Professional kitchens extend this color-coding to knives, containers, cleaning cloths, and even gloves. Everything has its place, and nothing crosses over.

Why This Matters More Than You Think

Bacteria don’t play fair. It can double every 20 minutes under the right conditions. And cross-contamination? It happens instantly.

Remember that “5-second rule” you learned as a kid? Total myth. Dr. Ronald Carter’s research proved that bacteria attach to food immediately upon contact. Yet 70% of people still believe dropped food is safe if you grab it fast enough.

Professional chefs learned this the hard way. They’ve seen what happens when systems fail. That’s why they treat invisible threats with the same respect a surgeon shows for sterile techniques.

The NASA-Level Temperature Game

You know what’s wild? The foundation of restaurant food safety was developed for space missions in the 1960s.

It’s called HACCP (Hazard Analysis Critical Control Points), and it was created to keep astronauts from getting sick in space. Now every serious restaurant kitchen uses it.

Your Meat Thermometer vs. Professional Equipment

While you’re guessing if that chicken is done, professional kitchens deploy 24/7 wireless monitoring systems that would impress NASA engineers.

They use sensors that monitor every refrigerator, freezer, and holding unit continuously. Real-time alerts ping smartphones when temperatures deviate even briefly. Cloud-based systems store temperature data for compliance audits.

The precision is insane. Professional thermometers provide 1-second readings with ±0.5°F accuracy. They calibrate equipment daily using ice baths and boiling water.

The Danger Zone That Could Ruin Your Day

Here’s something most home cooks don’t know: Foods spending more than two hours between 40°F and 140°F become biological weapons.

This isn’t restaurant paranoia. This is science.

In that temperature range, bacteria populations explode. We’re talking doubling every 20 minutes under optimal conditions. Leave that potato salad out for a few hours at your backyard BBQ? You might as well be playing Russian roulette.

Professional chefs understand time-temperature relationships that escape home cooks. Instead of just hitting target temperatures, they use scientific combinations. Chicken at 140°F for 30 minutes equals the safety of 165°F instantly—but results in juicier meat.

The Two-Hour Rule That Professionals Never Break

Time becomes a weapon in professional kitchens. The 2-hour rule isn’t a suggestion—it’s an absolute law.

Food spending more than two hours total in the danger zone must be discarded. Period. No exceptions. No, “but it smells fine.”

This includes:

- Warming up time

- Prep time

- Cooking time

- Cooling down time

Professionals track cumulative exposure across all handling. Something most home cooks never consider.

When One Hour Becomes the Limit

Here’s where it gets stricter: When ambient temperature exceeds 90°F, the safe window shrinks to one hour maximum.

Professional catering operations use this knowledge to design service timing. Meanwhile, home cooks routinely leave food on picnic tables for hours.

The FIFO system (First In, First Out) extends this time-based thinking to inventory management. New stock goes behind existing supplies. Dating systems track not just expiration dates but preparation times.

This time, consciousness stems from understanding pathogen behavior:

- Salmonella survives in beef for 381 minutes at 125°F but only 12 minutes at 140°F

- Listeria grows at temperatures as low as 9°F, surviving conditions that stop other bacteria

The Two-Step Process Most Home Cooks Skip

Think wiping down surfaces makes them safe? Think again.

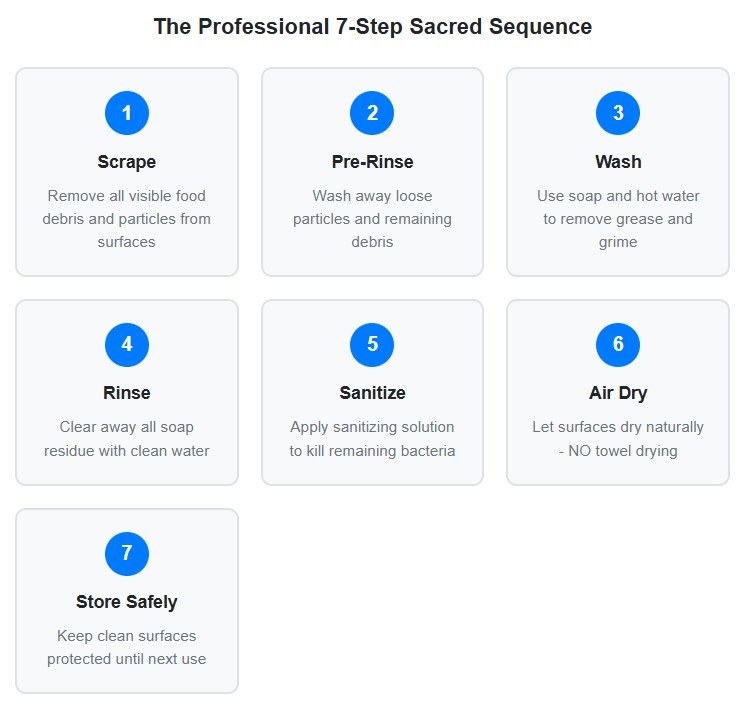

Professional kitchens follow a seven-step protocol that separates cleaning from sanitization—two completely different processes with different purposes.

The Sacred Sequence

The professional sequence never varies:

- Scrape – Remove visible debris

- Pre-rinse – Wash away loose particles

- Wash – Remove grease and grime

- Rinse – Clear away soap residue

- Sanitize – Kill bacteria

- Air dry – Let surfaces dry naturally

- Store properly – Keep clean until next use

Cleaning removes dirt. Sanitization kills bacteria. Skip either step and you compromise the entire process.

Why Your Kitchen Cleaner Might Not Be Enough

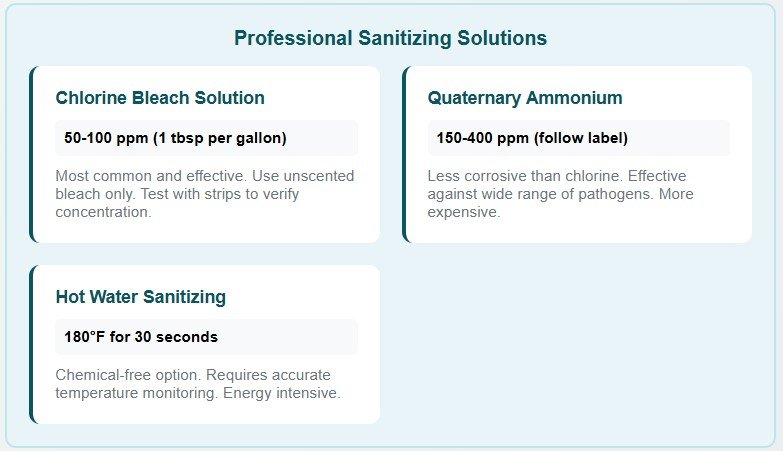

Sanitizing solutions require precise concentrations—50-100 ppm for chlorine solutions. Home cooks who spray “kitchen cleaner” around food prep areas often use products that are either too weak to sanitize or too strong for food contact surfaces.

Professional kitchens maintain color-coded cleaning cloths that match their cutting board systems. Red cloths clean raw meat areas, never touching vegetable prep surfaces.

Air drying is crucial—towel drying recontaminates sanitized surfaces with bacteria from fabric fibers.

The Celebrity Chef Reality Check

Want to know something shocking? A Kansas State University study of 100 cooking shows found 88% of celebrity chefs didn’t wash their hands after handling raw meat.

If TV chefs mess this up, imagine what’s happening in home kitchens across America.

Professional kitchens combat this with placed hand-washing stations, sanitizer dispensers, and supervisory oversight that home kitchens can’t replicate.

Bringing Professional Standards to Your Home Kitchen

- Purchase instant-read thermometer

- Learn internal temperature standards

- Practice 1-second readings

- Test thermometer accuracy

- Set up color-coded cutting boards

- Create sanitizing solution

- Practice 7-step cleaning process

- Establish separate prep areas

- Implement 2-hour rule tracking

- Set up multiple timers

- Monitor danger zone exposure

- Practice rapid cooling techniques

- Organize FIFO storage system

- Label all containers with dates

- Create mise en place workflow

- Establish daily cleaning routine

- Wash hands for 20 seconds

- Check thermometer accuracy

- Prepare sanitizing solution

- Set up color-coded boards

- Check expiration dates

- Use timers for danger zone tracking

- Check internal temperatures

- Clean as you go

- Never reuse cutting boards

- Monitor holding temperatures

- Cool foods rapidly to 40°F

- Label leftovers with dates

- Follow 7-step cleaning process

- Store using FIFO method

- Clean and sanitize all surfaces

- Deep clean refrigerator

- Check storage container dates

- Replace sanitizing solutions

- Inventory and rotate stock

- Review safety procedures

The good news? You don’t need a $50,000 kitchen renovation to cook like a pro.

Start With These Game-Changing Tools

Invest in a real thermometer. Professional-grade instant-read models like the ThermoWorks Thermapen One provide the accuracy that prevents guesswork. Leave-in probe thermometers with high/low alarms monitor large roasts continuously.

Create your color-coding system. While seven colors might be excessive for home use, three cutting boards can provide critical separations:

- One for raw animal proteins

- One for cooked foods

- One for fresh produce

Make sanitizing solutions. Mix 1 tablespoon of unscented bleach per gallon of water. Store in spray bottles for easy application. Remember: clean first to remove debris, then sanitize to kill bacteria.

Develop Professional Habits

Track time religiously. Use phone timers to monitor how long foods spend in the danger zone. Professionals never guess at timing because the stakes are too high.

Implement FIFO rotation. Store new purchases behind existing stock. Date everything, including leftovers. Maintain the strict 3-4 day maximum for cooked foods in refrigeration.

Think like a pro. As Anthony Bourdain said, “Bad food is made without pride, by cooks who have no pride, and no love.” Professional standards aren’t about following more rules—they’re about understanding the science behind food safety.

The Mise en Place Mindset

Professional chefs live by “mise en place”—everything in its place. This isn’t just about organization. It’s about creating predictable workflows that eliminate safety risks.

Use uniform, stackable containers with identical lid sizes. Label everything with contents and dates. Place labels consistently for easy scanning.

Visual clutter creates safety risks by providing hiding spots for contamination and making thorough cleaning impossible.

The Future of Food Safety Is Already Here

Technology continues evolving. AI systems now predict contamination risks before they occur. Wireless sensors provide 24/7 monitoring that eliminates human error. Blockchain systems enable instant traceability during outbreaks.

But the fundamental principles remain constant: respect for ingredients, systematic processes, and understanding that food safety isn’t about following rules—it’s about protecting the people we feed.

Your Kitchen, Your Choice

Professional chefs learned these lessons through tragedy. The Jack in the Box outbreak. The Chi Chi’s closure. Countless smaller incidents that never made headlines.

Their systematic approach to food safety represents hard-won wisdom that every home cook can use to protect their family while cooking better food.

You have two choices:

Continue guessing and hoping for the best. Or adopt the proven methods that keep professional kitchens safe.

Which one sounds better to you?

Ready to transform your kitchen safety game? Start with one change this week. Grab a quality thermometer, set up a simple color-coding system, or master the clean-then-sanitize protocol. Small changes, massive protection.

Your family (and your dinner guests) will thank you.